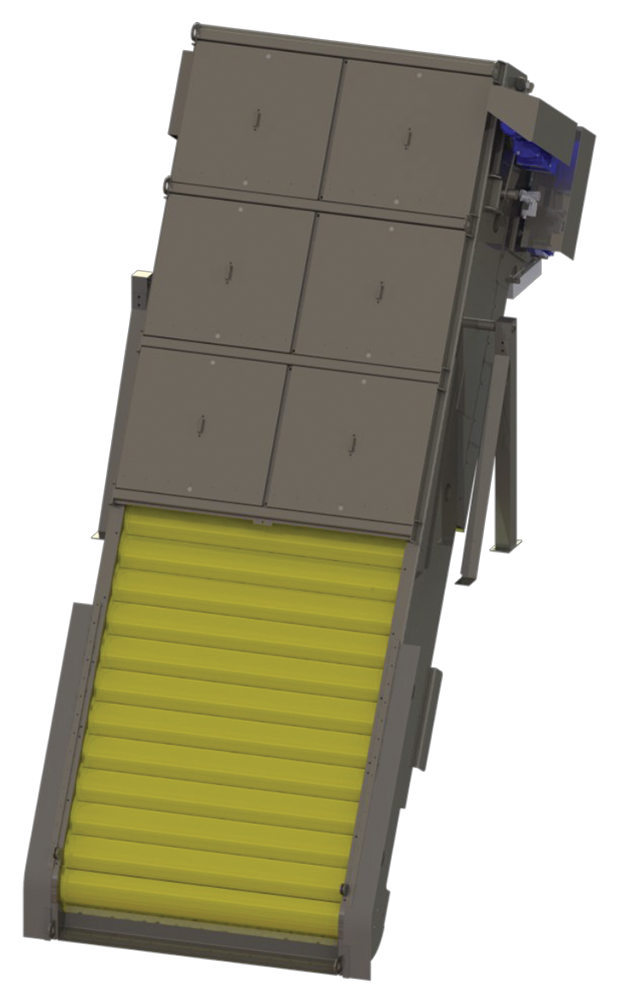

Perforated Plate Screen

Perforated Plate Screen

The PPS consists of a filtration area made with perforated plate panels with a predeter-mined perforation. The panels are moved by a double chain (on each side of the screen frame). The panels hold the particles, thus create an occlusion that generates a rise in the up stram level; when the upstream water level reaches a pre-set level, the motor starts so the panels move toward the discharge.

A rotating brush system and a spray bar en-sure the complete cleaning of the panel du-ring the screenings discharge.

MOC: stainless steel AISI 304 / 316

Length: the maximum length depends on the overall

specifications Standard Inclination: 45-75°

Drive: the maximum power depends on the incli-nation, the flow rate and the length required

APPLICATION FIELDS

– Wastewater

– Industrial plants